DT-220

APPLICATIONS

FEATURES

SPECIFICATIONS

OPTIONS

Download data sheet in PDF format

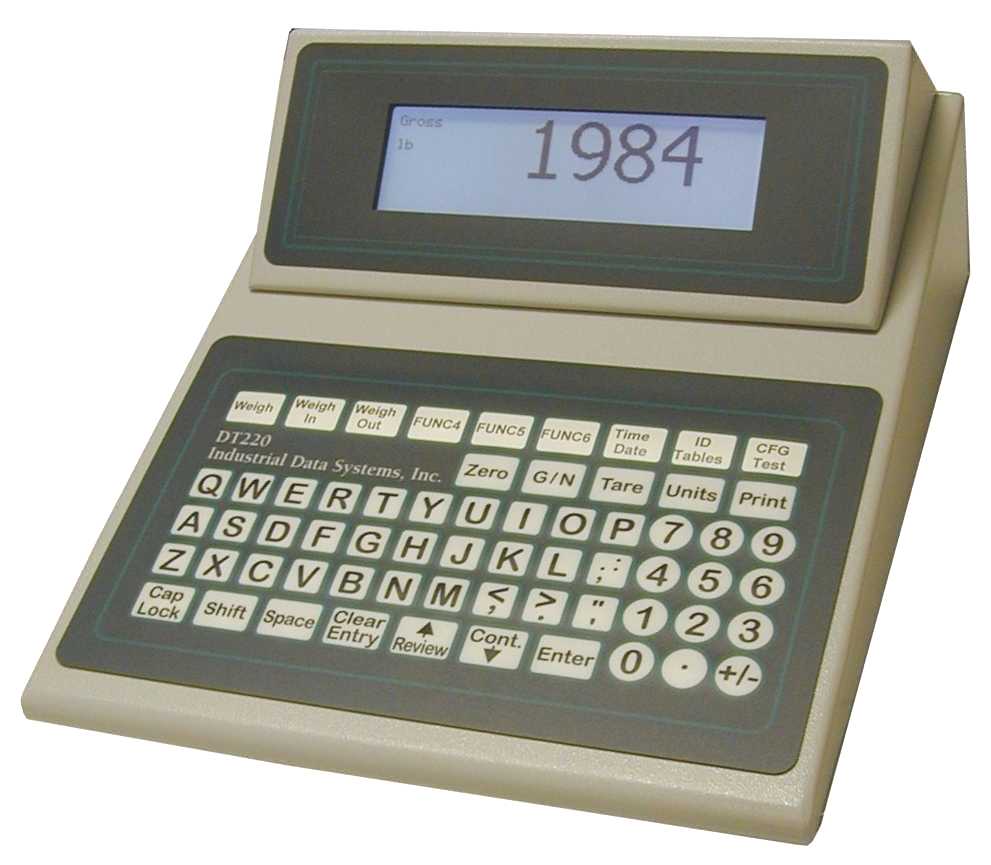

The IDS DT-220 is a Programmable Data acquisition Control Terminal & System Integrator with a rugged design

and state-of-the-art electronics technology. The DT-220 is the next generation data terminal designed to bring

plug-in enhancement features to new or existing systems.

(Available in NEMA enclosures)

The compact design of the DT-220 combines flexibility and speed with an easy to use operator interface.

This versatile and cost-effective terminal is designed for use in industrial environments to perform the following functions:

Data Collection – Collects data from A/D signals, serial communication ports, TTL inputs, and the alpha/numeric keyboard.

The DT-220 allows you to perform a number of applications. These range from weigh-in weigh-out vehicle/trailer/container ID

gross, tare, net weighing operations to more complex tasks such as multi-container/axle auto weighing, check-weighing,

force measurement, auto-sorting, controlling multi-Ingredient formula batching systems, bulk-weighing,

vessel/hopper/silo loss in weight, bagging packers, various other sophisticated trip level event monitoring and

process control tasks.

The IDS DT Series terminals are being used for many important applications in transportation, agriculture, mining,

construction, material handling, packaging and manufacturing. Applications are unlimited for the user who

is capable of writing a basic program. For those who prefer turnkey products, Industrial Data Systems offers

a constantly growing number of standard applications or we can program the DT-220

around your specific application. Consult factory for custom programming quote.

PROGRAM DESCRIPTION

The DT-220 is fully programmable in an easy and flexible macro language called Scale Basic. In addition to the built-in modes of operation, Scale Basic allows you to customize the operation of the DT-220 to meet your application requirements. The Scale Basic language provides various commands and functions that include: Math operations, I/O control, setpoints, timers, data entry, ID storage, message display, and program sequence control among others. Programming the DT-220 can be performed through the keyboard or a PC using the optional EZ-LINK software that greatly facilitates setup and programming.

The DT-220 incorporates a 8 line x 40 char LCD display with Back Lighting to facilitate operator prompting, messaging.

A 63-key sealed membrane keypad with audible and tactile feedback design for data entry and is immune to dust and liquid

spills.

Programmable in Scale Basic macro language for application development (event driven).

Provides built-in interfaces to input a wide variety of indicators data streams and Simulates A&D, Condec, Weigh-Tronix

and Ohaus communication output data stream protocols. Provides user configurable serial output protocols. Password

protection to prevent unauthorized access to data or tampering.

Built in comprehensive diagnostic functions for analog/scale, memory, display and I/O ports. Hot-keys for configuration

and diagnostics menus. Primary and secondary units with conversion factor. Digital port for relay control, Parallel

Centronics printer interface port. 3 full duplex serial ports (2 isolated RS232): RS232, RS485 and 20mA current loop.

Selectable baud rates and data formats. Barcode/RFID scanner/reader input interface. Time and Date Clock Leap Year compliant.

32MB non-volatile flash memory provides over 8000 IDs/Transactions/Formulas storage. Selectable address for multi-drop

RS485 network interface. PS/2 external keyboard interface port.

Display : 8 lines x 40 char LCD display with Back Lighting.

Keyboard : 63-key sealed membrane with audible and tactile feedback design.

Clock : Leap Year compliant Time/Date.

Flash Memory : 32MB provides over 8000 ID storage.

Watchdog Timer : For Fault tolerant operation.

Communications

Serial Port 1: Full duplex RS232 or 20mA current loop (Isolated RS232).GENERAL SPECIFICATIONS

Power: 80/260VAC ±10% @ 50/60Hz internal A/C power supply.

Power Consumption operating: 3W @ 115VAC.

Environmental: 32 F to 115 F (-10 C to 40 C), to 80% non-condensing

relative humidity.

No external ventilation required. The unit is unaffected by non-corrosive,

non-conductive dust, and moderate RF fields.

Enclosure Construction: Painted Cold Rolled Steel (NEMA Available).

Size: 8.575" wide,

11.20" deep, and 4.10" high (217.805 x 284.48 x 104.14 mm).

Weight: 7.12 lb (3.22 kg).

Warranty: One year limited.

24 bit Analog Input Module: Internal Load Cell/Scale Interface Module.

Analog Output Module: Fully Isolated 0-5, 0-10 VDC or 0-24, 0-20, 4-20 mA; 16 bit resolution.

Relay Module: 4 & 8 channel external optically isolated relay modules.

External Keyboard: PS/2 Keyboard (NEMA Available)

EZ-LINK Software: PC software; facilitates configuration and Scale Basic programming and

Data Base maintenance.

Custom Enclosed Systems: Consult factory.

Custom Programming: Consult factory.

Try one of our MADE IN THE USA Digital Instruments

Industrial Data Systems, Inc.

3822 E La Palma Ave, Anaheim CA. 92807

Phone 714-921-1353

Outside of CA sales 800-854-3311